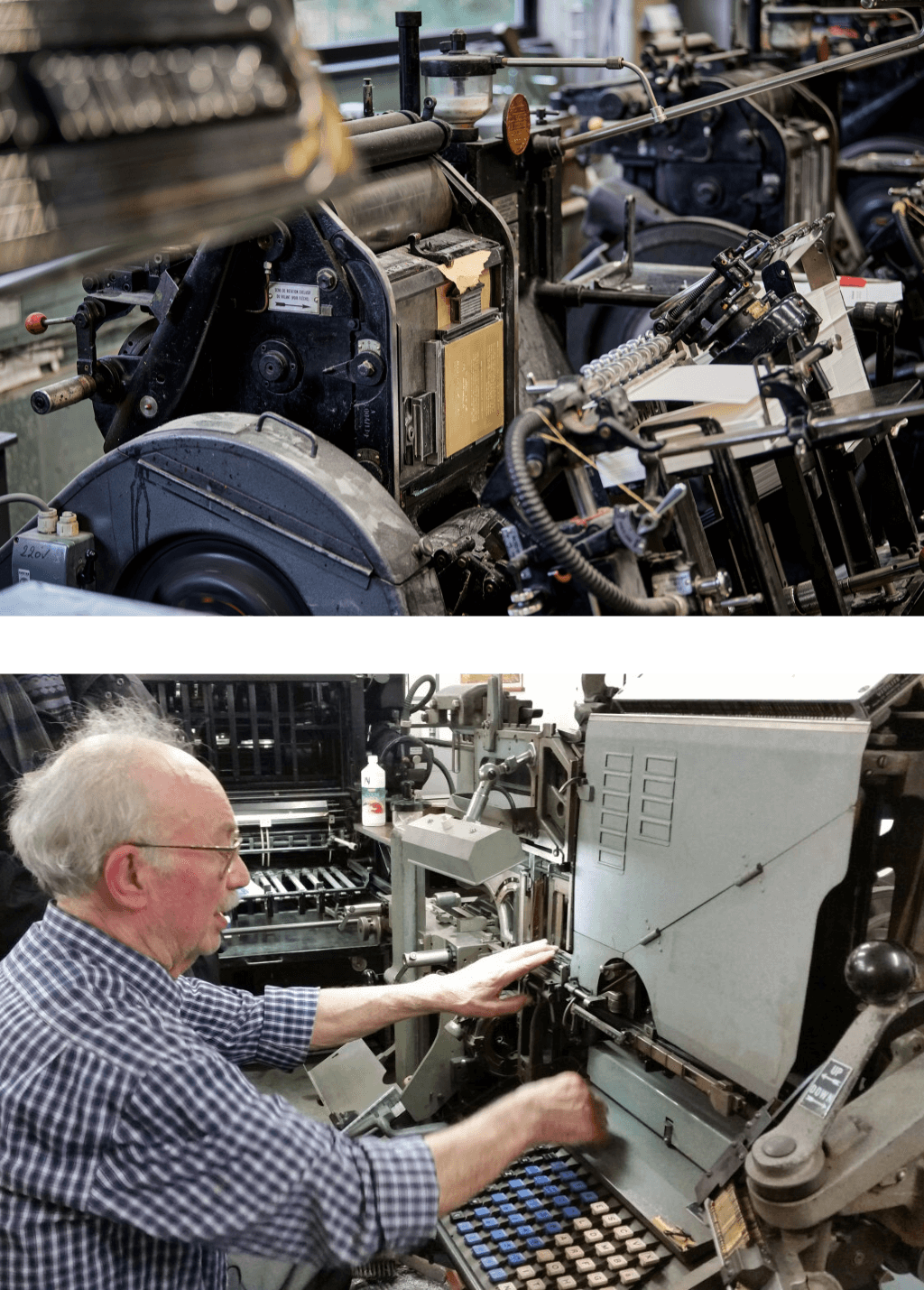

History

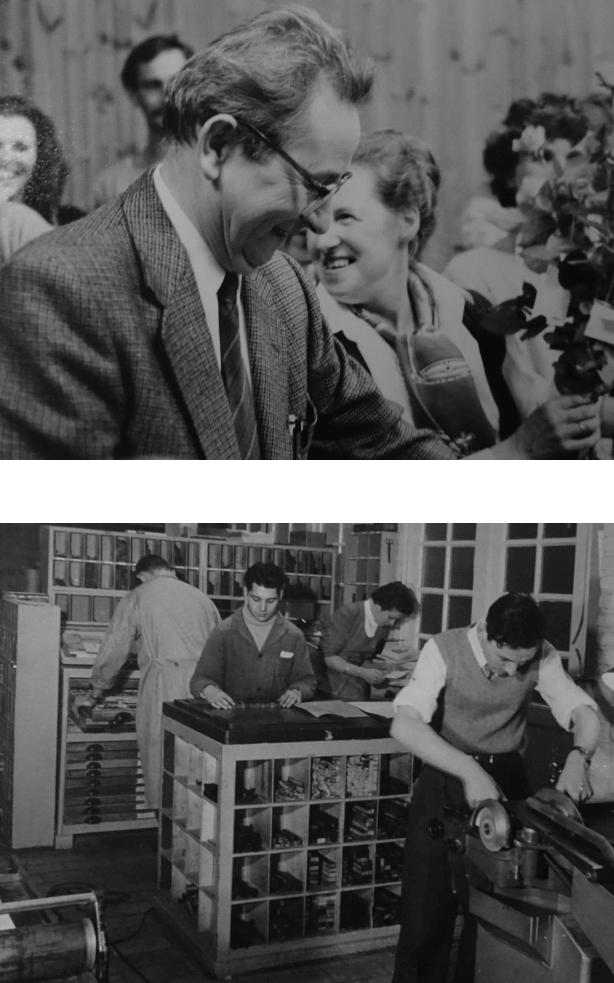

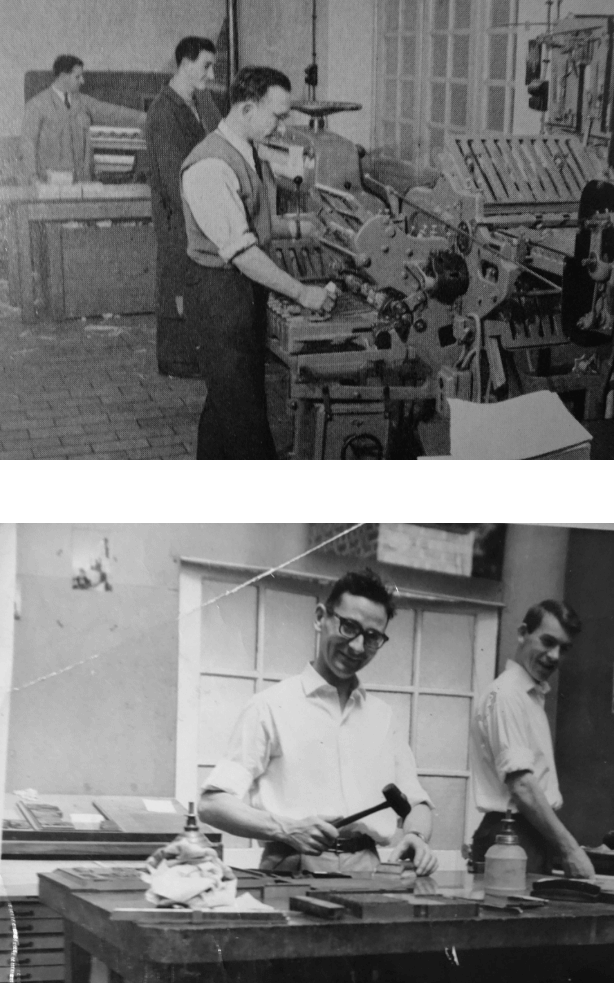

WE CRAFT YOUR PRINTS WITH PASSION SINCE 1958

More than 60 years and several generations later, DRIFOSETT S.A. maintains the highest level of requirements to satisfy you.

Discover our history

Foundation

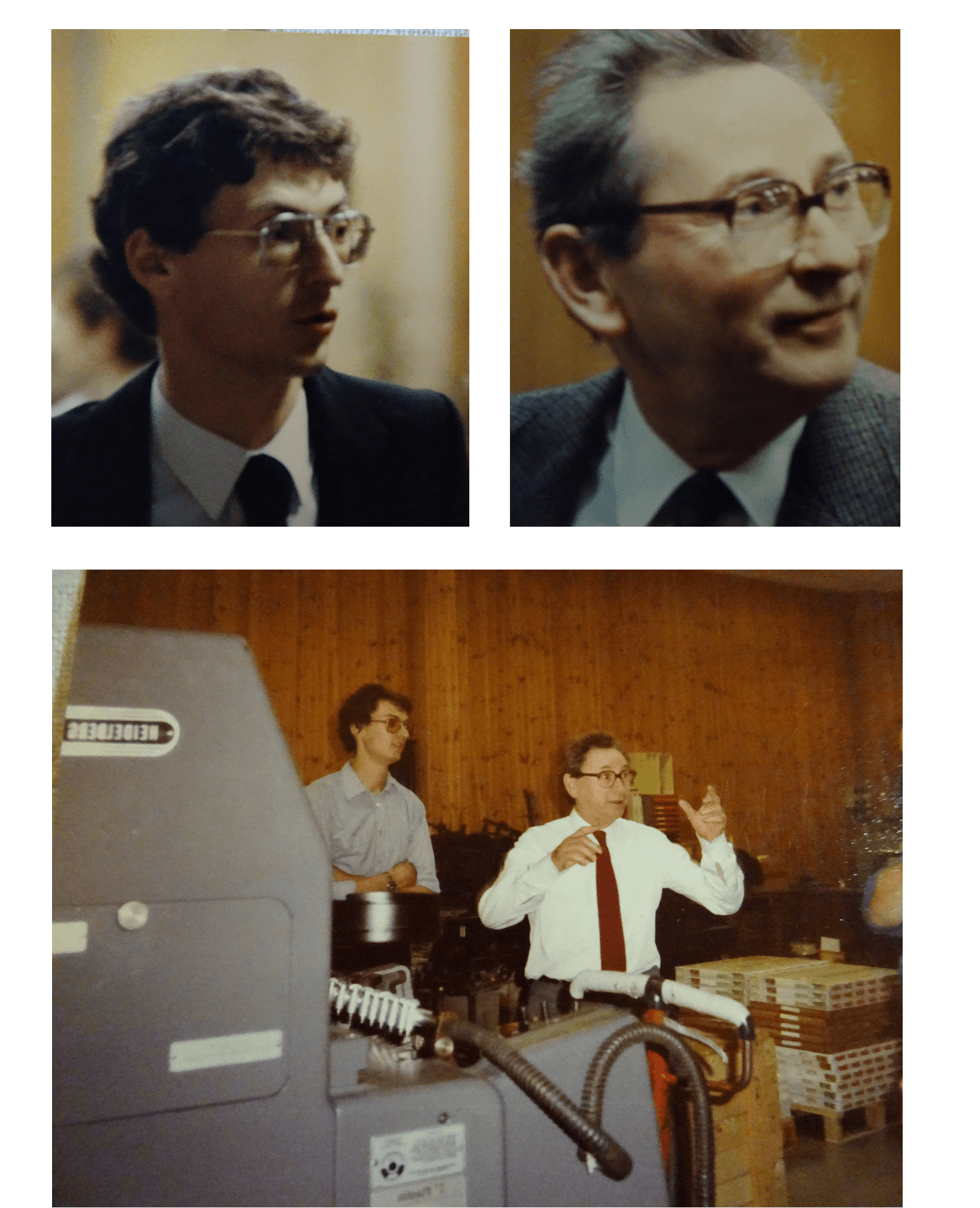

ANOTHER GENERATION: DRIFOSETT PRINTING SPRL

FIRST PHASE OF MODERNIZATION

From generation to generation

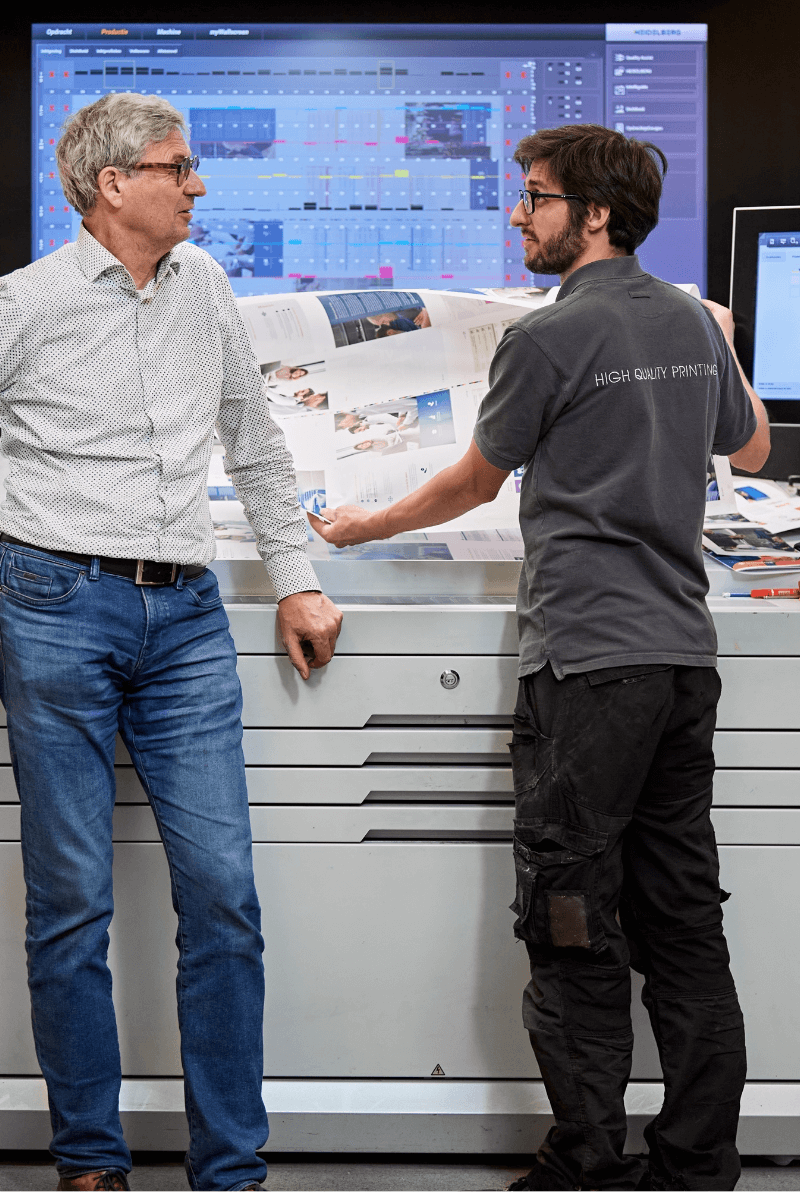

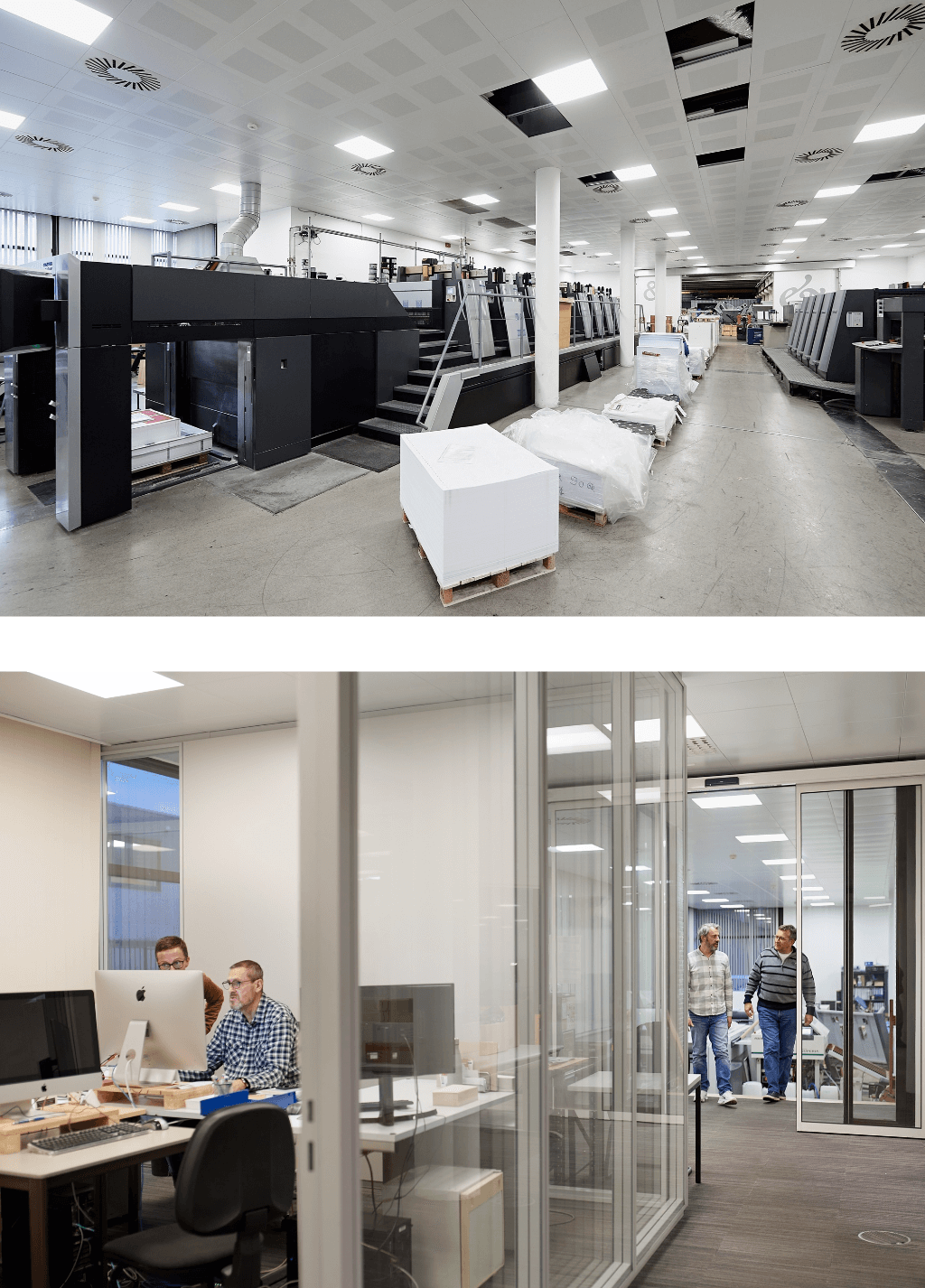

IT MOVES AND MODERNIZES AGAIN

Since then, Drifosett Printing S.A. has continued to acquire equipment that allows it to offer more and more to its customers. Numerous investments in finishing have been made to complete its equipment.

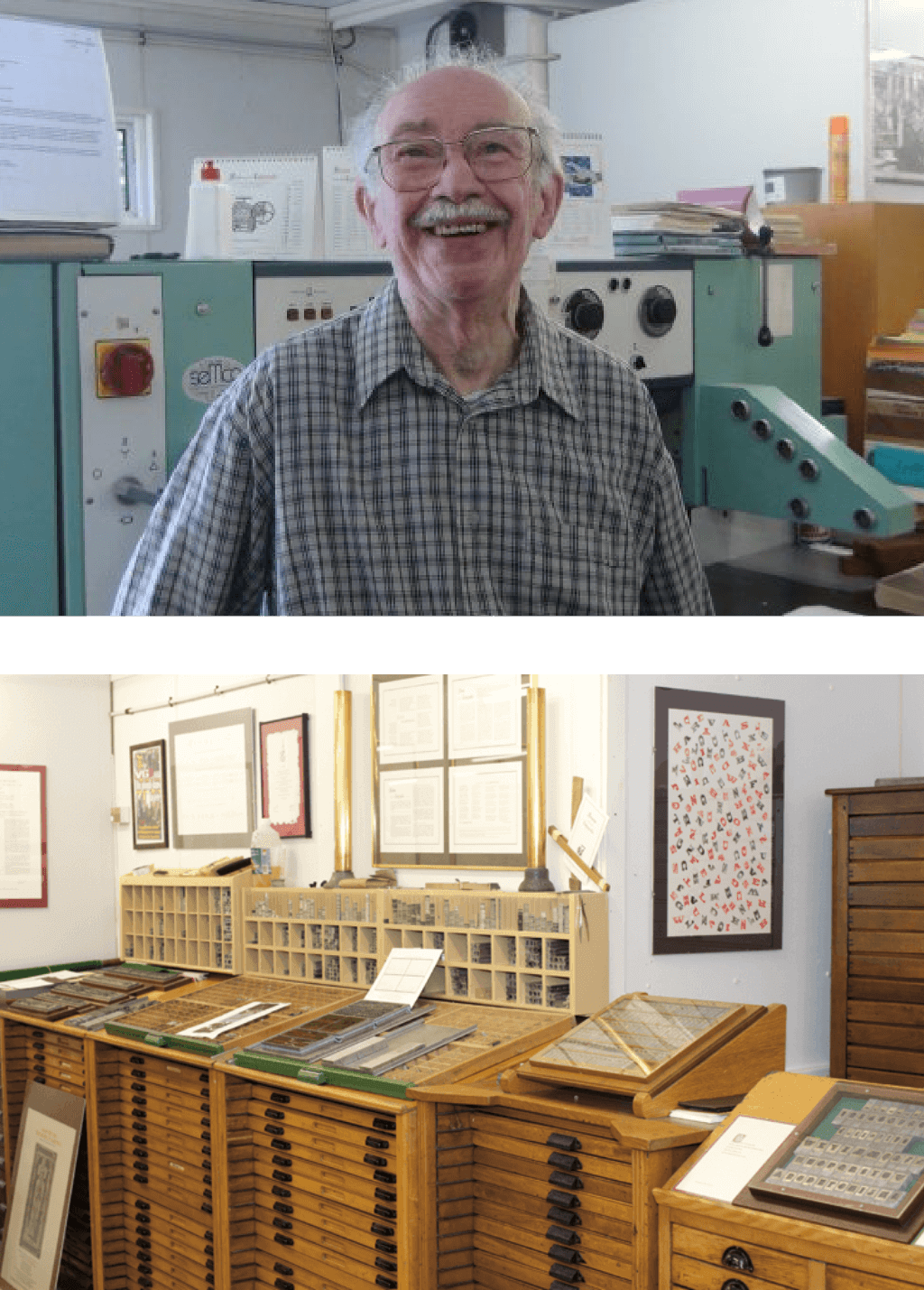

PAST PRESENT FUTURE

It is also in 2013 that the first digital press is integrated into the company's machine park.

THE PREPRESS TO SERVE YOU

PUSH THE WALLS BACK UP

A large part of the Heidelberg building in Evere was therefore converted to bring together the various activities that had been brought together in recent years.

Drifosett also takes its first steps in large format printing by investing in an XL106P-8P offset press with Led UV technology.

A growing team

Several companies and families joined the adventure by bringing their know-how. The Landerwijn family, for example, has a rigorous finishing and sophisticated binding process, while the van Ruys and Steenwerckx families are very efficient and complete.

It is also thanks to the good will and motivation of each member of our staff that every day the company is equipped with new techniques and possibilities to realize your every wish.

It is then the new modes of digital impressions on multi-supports & multi-formats of the Gillis company which join our walls.

A GLOBAL PHENOMENON CALLED COVID

A NEW DIGITAL COMMUNICATION

Or how to make paper, the smell of ink (vegetable!) and the new modes of communication cohabit!

What if your projects could write a new page?

Contact us